Sebopeho

Lisebelisoa

Vin 1.4404 / Aisi 316l, Din 1.8539 / Aisi 9044l

Monel, Photosonel, Junes Steel, Hasstoy

Lisebelisoa tse ling tse fumanehang ka kopo.

Phokotso ea filthara: 1 -200 likonopo

Boholo

500mmx1000mm, 1000mmx1000mmmmmmmm

600MMXX1200, 1200MMX1200mmmmmmm

1200mmx15MMMMMMMMMMMMMMMMXTOMSmmmmm

Boholo bo bong bo fumanehang ka kopo.

Litlhaloso

| TLHOKOMELISO - Pula ea Plate Plate Thoush | ||||

| Tlhaloso | Ho fola | Sebopeho | Botenya | Poroniki |

| μm | mm | % | ||

| SSM-P-1.5t | 2-100 | 60 + 30 + φ4X5PX1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + 30 + φ4X5PX1.5t | 2.5 | 35 |

| SSM-P-P-3.0t | 2-200 | 60 + φ6x8px2.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | 30 + 20 + φ8X10PX2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 + 30 + 16 + 18 + φ8x10Px3.0t | 5 | 55 |

| SSM-P-6.0t | 2-250 | 30 + 30 + 17 + φ8x10Px4.0t | 6 | 50 |

| SSM-P-7.0t | 2-250 | 30 + 16 + 32 + φ8XTPX5.0t | 7 | 50 |

| SSM-P-8.0t | 2-250 | 30 + 16 + 10 + φ8x10Px6.0t | 8 | 50 |

| Bothusi ba poleiti ea ho putlama le sebopeho sa mehoe e ka etsoa ho latela litlhoko tsa mosebelisi. | ||||

Ho bua ka mantsoe, haeba e sebelisoa ho li-filthara tsa 'mele, sebopeho sa poleiti se sephara se ka ba maemong a mekhahlelo a mekhahlelo e mehlano ea mekatola le ho putlama polane e senyehileng hammoho.

Eo ke 100 + filyal "100 + 12 + 12/64 + 64 + 64 + 43t (kapa e le 'ngoe e otla poleiti)

Boghneke ea ponahalo ea pushing e boetse e ne e le ho itšetleha ka tlhoko ea hau ea khatello.

Sehlahisoa sena se loketse libaka tsa khatello tse phahameng kapa khatello e phahameng ea ho rarolla indastering e tsoelang pele ea indasteri ea pharma le la lik'hemik'hale le litlhokahalo tsa tlhahlobo.

Likopo

Lijo tsa lijo le tse fapaneng, tšoaro ea metsi, e tlosang lerole, meriana, k'hemik'hale, Plymer, joalo-joalo.

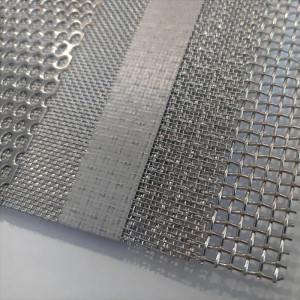

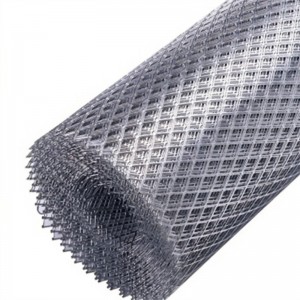

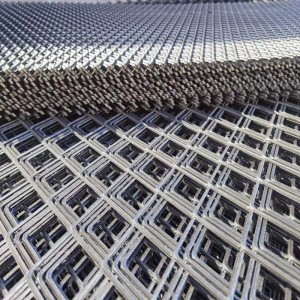

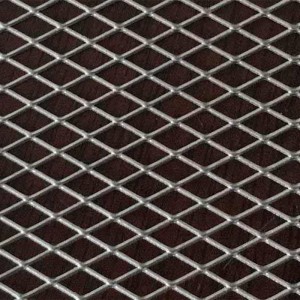

Mesh e pentiloeng e senyehileng ke mofuta o mocha oa thepa e tloaelehileng (e nang le tšepe e nang le 304 kapa 3160). Plate ea ho putlama e ka khethoa ka bophahamo bo fapaneng ho latela litlhoko, 'me letlooa le utloang e ka ba likarolo tse le' ngoe kapa tse ngata. Ka lebaka la poleiti ea ho putlama e le tšehetso, Mesh e kopaneng e na le matla a mangata le matla a mochini. Ho sebetsoa ha bobeli ha ho na le ho nepahala ha moea oa ho hlaka ho lohiloeng, empa hape le ka matla a poleiti ea moferefere. E ka sebetsoa ka cylindrical, li-disc, lakane, li indasteri ea metsi, ho ba lik'hemik'hale, jj.

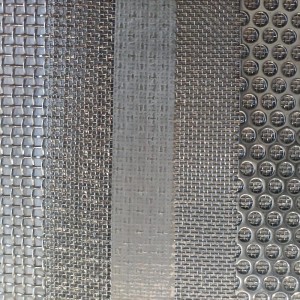

Sebopeho se nang le litšila se senyehileng se entsoe ka ho silafatsa skeleton e sa tsitsang mme filya ea menshe ka 'mele, kahoo e na le litšobotsi tse latelang:

(1) ho thatafala hantle le matla a phahameng. Ka lebaka la tšehetso ea poleiti ea plate e potileng, e na le matla a matle le matla a hatellang har'a Meshe e nyetsoeng.

.

(3) Ho bonolo ho se hloeka, filthara e ka holimo e amoheloa, haholo-holo e loketse ho khutla.

(4) Ha e holofetse habonolo, sebopeho sa mesi e lokisitsoe, boholo ba lekhalo ke junifomo, 'me ha ho na motho ea foufetseng. (5) Ho hanyetsa khanyetso, mocheso o phahameng oa mocheso o phahameng, o ka mamella mocheso o phahameng oa 480 ° C.