Sebopeho

Model One

Model tse peli

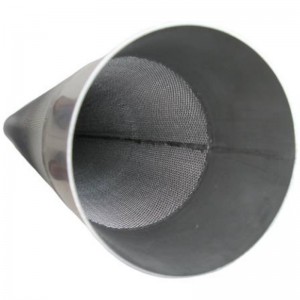

Meshi e 'meli kapa e meraro e lenngoeng e le lerootho

Model tse tharo

Lisebelisoa

Vin 1.4404 / Aisi 316l, Din 1.8539 / Aisi 9044l

Monel, Photosonel, Junes Steel, Hasstoy

Lisebelisoa tse ling tse fumanehang ka kopo.

Phokotso ea filthara: 1 -200 likonopo

Litlhaloso

| Tlhaloso - Bobeli kapa tse tharo - tse tharo - tse nang le moea o senyehileng | |||||

| Tlhaloso | Ho fola | Sebopeho | Botenya | Poroniki | Boima |

| μm | mm | % | kg / ㎡ | ||

| SSM-T-0.5T | 2-200 | Filthara Walter + 80 | 0.5 | 50 | 1 |

| SSM-T-1.0t | 20-200 | Filthara Walter + 20 | 1 | 55 | 1.8 |

| SSM-T-1.8T | 125 | 20 + 24/1 / 110 | 1.83 | 46 | 6.7 |

| SSM-T-2.0t | 100-900 | Filya Royar + 10 | 1.5-2.0 | 65 | 2.5-3.6 |

| SSM-T-2.5t | 200 | 12/64 + 64/12 + 12/64 | 3 | 30 | 11.5 |

| Lipolelo: sebopeho se seng se fumanehang ka kopo | |||||

Likopo

Lintlha tsa koae, matlo a robala a mangata, likarolo tsa Aeetions, li tsamaisa terompeta ea li-vneumatic.etc.

Ho nepahala ha liphallelo tsa tšepe ea tšepe le sentsoeng ke tšepe

Karolo e mpe ea tšepe e na le litlolo tsa khale, ho ikhula hantle, ho hloekisoa habonolo, 'me ha ho na karohano ea lintho tse ngata.

Lisebelisoa tsa tšepe tse se nang thuso tsa tšepe li sebelisoa haholo bakeng sa ho thella ha polyester, mecha

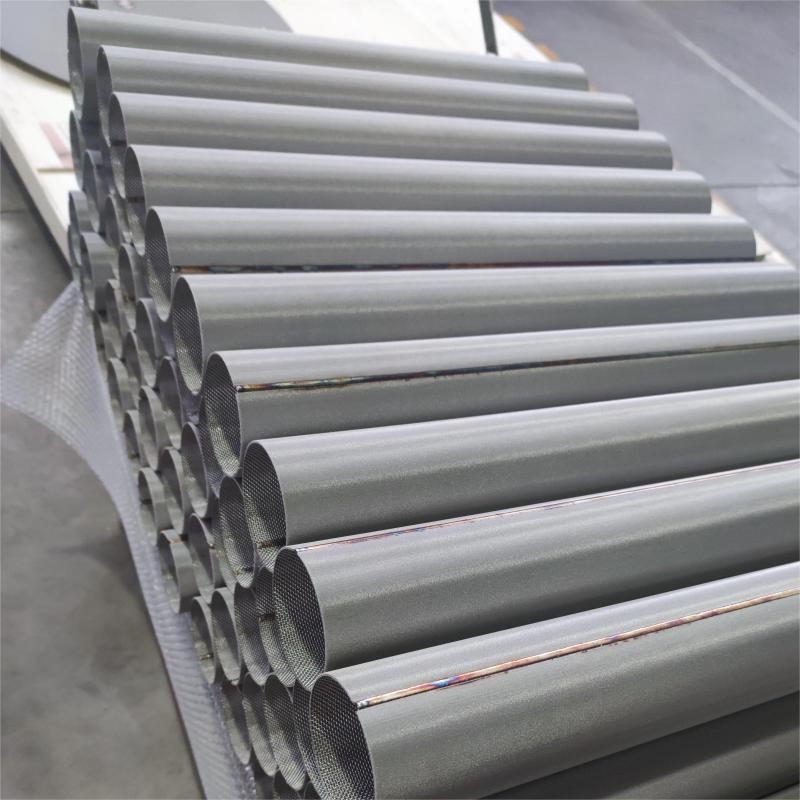

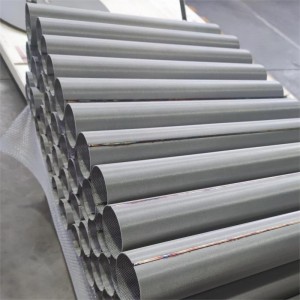

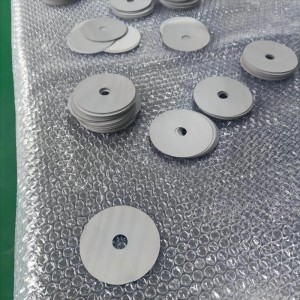

Lisebelisoa tsa tšepe tsa tšepe tsa tšepe li ile tsa senya mebala ea cylindrical e koahela boholo le litlhaloso tse fapaneng. Litlaleho tsohle tse boholo li ka etsoa ho latela litlhoko tsa bareki, 'me lihlahisoa tse loketseng le tsona li ka etsoa le ho khothalletsoa ho latela maemo le litlhokahalo.

Boitsebiso: Steels: steel e se nang thuso

Melemo e mene e mene le litšobotsi tsa tšepe tsa tšepe tsa tšepe tsa tšepe tse entsoeng ka cylindrical

1. Theknoloji ea theknoloji e nka nako ea machabeng e phahameng haholo, le ts'ebetso ea mahlale a mantlha (re tla tsoela pele ho thefala le ho hola, 'me ho tla ba le theknoloji ea filtration ho sebeletsa lefatše nakong e tlang);

2. Mofuta oa hona joale oa ho nepahala: ho tloha likomki tse 100 le holimo, ka mefuta e mengata ea ho nepahala;

3. Matla a phahameng a phahameng, ho tsitsa hantle le ho nepahala ho tsitsitseng haholo. Ts'ebetso ea khatello ea khatello ea khatello e phahameng e ikhethile haholo, haholo-holo e loketseng liketsahalo tse hlokang matla a phahameng a matla le boholo ba filityric sical collel.

4. Kameho e tlase ea filthara le ho loka haholo;

5. Lintho tsena ke tšepe ea lijo tsa mofuta oa boleng bo holimo haholo, e nang le ho khathatseha haholo;

6 Potoloho e tsoetseng pele ea ho fana ka puo e tsoetseng pele lefatšeng, karolo ea filthara e bonolo ebile e bonolo ho e hloekisa, ntle ho lintho tse ling tsa ho oela;

7. Khanyetso e bata haholo e ntle haholo, 'me mocheso o tlase o ka fihla ka tlase-li-degrees (khethehileng mocheso o tloaelehileng o sebetsang) o ka etsoa);

8. Ho hanyetsa mocheso ho lokile haholo, 'me mocheso oa ts'ebetso o ka fihla ka holimo ho likhato tse 650 (mocheso o ikhethang oa ho sebetsa oa Ultra o ka etsoa);

9. Hanyetsa libaka tse sebetsang tse kang alkali tse matla tse matla le lijalo tse matla tsa asiti;

10. Mechine ea lifilimi e holim'a motlakase, 'me setene sa mesh se boreleli, ka hona e loketse tšebetso e nkileng nako e telele, e sa sebelisoeng ke boitsebiso bofe kapa bofe ba filthara ba;

11. Palo ea kopo e pharaletseng haholo, e loketseng likhase tse fapaneng, li-solas, litlolo, ho phatloha ka mokhoa o hlakileng,

12. The overall performance is obviously superior to other types of filter materials such as sintered powder, ceramics, fiber, filter cloth, filter paper, etc. It has special advantages such as high precision, high efficiency and long life.