Tlhaloso

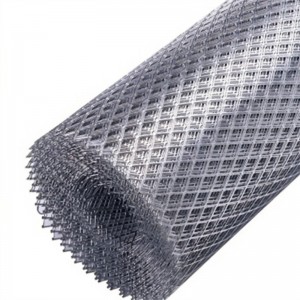

lintho tse bonahalang: 304, 304L, 316, 316L, 317L, 904L, Duplex tšepe joalo-joalo.

| Litlhaloso tsa Twill weave | |||||||

| Khoutu ea sehlahisoa | Mesh e hlabang | Weft mesh | Wire bophara | Aperature | Sebaka se bulehileng | ||

| intshi | mm | intshi | mm | (%) | |||

| STW-30/0.4 | 30 | 30 | 0.0157 | 0.399 | 0.0176 | 0.45 | 28.0 |

| STW-40/0,35 | 40 | 40 | 0.0138 | 0.350 | 0.011 | 0.29 | 20.1 |

| STW-40/0.4 | 40 | 40 | 0.0157 | 0.400 | 0.009 | 0.24 | 13.7 |

| STW-46/0,25 | 46 | 46 | 0.0100 | 0.254 | 0.012 | 0.30 | 29.2 |

| STW-60/0,25 | 60 | 60 | 0.0100 | 0.254 | 0.007 | 0.17 | 16.0 |

| STW-80/0.17 | 80 | 80 | 0.0067 | 0.170 | 0.006 | 0.15 | 21.6 |

| STW-100/0.12 | 100 | 100 | 0.0047 | 0.120 | 0.005 | 0.13 | 27.8 |

| STW-120/0.11 | 120 | 120 | 0.0043 | 0.110 | 0.004 | 0.10 | 23.1 |

| STW-150/0.8 | 150 | 150 | 0.0031 | 0.080 | 0.004 | 0.09 | 27.8 |

| STW-200/0.06 | 200 | 200 | 0.0024 | 0.060 | 0.003 | 0.07 | 27.8 |

| STW-270/0.04 | 270 | 270 | 0.0016 | 0.041 | 0.002 | 0.05 | 32.3 |

| STW-300/0.038 | 300 | 300 | 0.0015 | 0.038 | 0.002 | 0.05 | 30.3 |

| STW-325/0.036 | 325 | 325 | 0.0014 | 0.036 | 0.002 | 0.04 | 29.7 |

| STW-350/0.035 | 350 | 350 | 0.0014 | 0.035 | 0.001 | 0.04 | 26.8 |

| STW-400/0.025 | 400 | 400 | 0.0011 | 0.028 | 0.001 | 0.04 | 31.4 |

| STW-500/0.025 | 500 | 500 | 0.0010 | 0.025 | 0.001 | 0.03 | 25.0 |

| STW-635/0.02 | 635 | 635 | 0.0008 | 0.020 | 0.001 | 0.02 | 24.2 |

Tlhokomeliso: Litlhaloso tse khethehileng le tsona li ka fumaneha ho latela tlhoko ea bareki.

Likopo: E sebelisoa haholo ho hlahlobisisa likaroloana le ho sefa, ho kenyeletsoa ho sefa ha petrochemical, ho sefa lijo le meriana, ho etsa polasetiki hape le liindasteri tse ling.

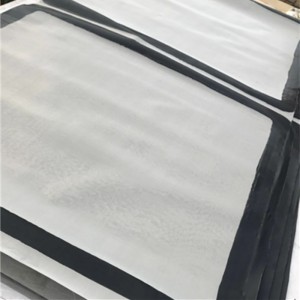

Bophara bo tloaelehileng bo pakeng tsa 1.3m le 3m.

Bolelele bo tloaelehileng ke 30.5m(100 maoto).

Mefuta e meng e ka etsoa ka mokhoa o ikhethileng.

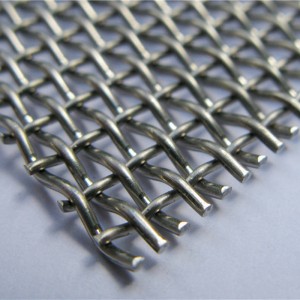

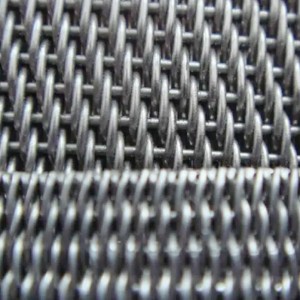

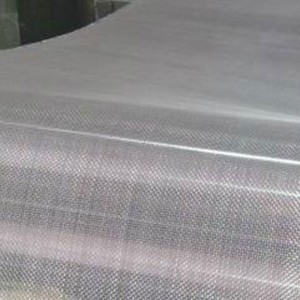

Joalo ka ha lebitso le bolela, lesela la mesh ea tšepe ke lesela la letlooeng le lohiloeng ka terata ea tšepe e sa hloekang.Lesela la terata ea tšepe e sa hloekang le na le matla a phahameng le ho hanyetsa acid le alkali.E loketse lik'hemik'hale, meriana, bophelo bo botle, indasteri e khanyang, puisano ea mehala, peterole le liindasteri tse ling.Ho hlahloba le ho sefa lisebelisoa tsa granular le ho sebelisoa mabanta a conveyor, ho baka, ho tlatsa, joalo-joalo.

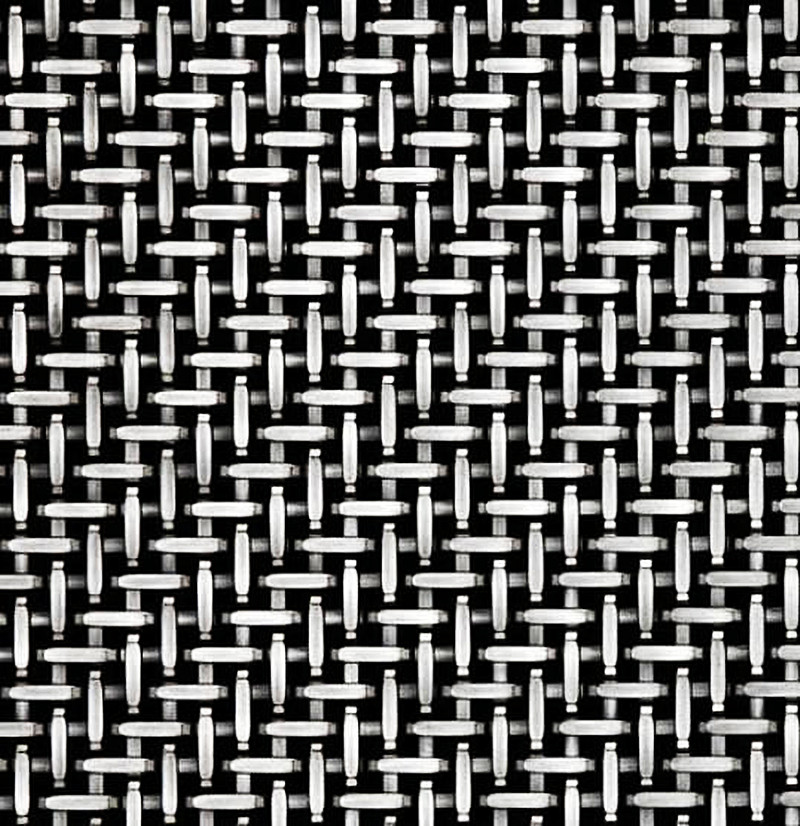

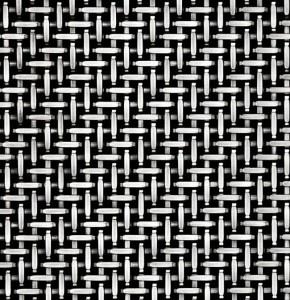

Weave/ Ketso ya ho loha: ho loha ha bonolo le ho loha ka twill

Likarolo: ho hanyetsa acid, ho hanyetsa alkali, ho hanyetsa mocheso o phahameng, matla a ho tsitsa le ho hanyetsa abrasion

Lisebelisoa: E sebelisetsoa ho sieving le ho sefa tlas'a maemo a asiti le a alkali tikolohong, joalo ka letlooa la seretse indastering ea peterole, joalo ka letlooa le sieve indastering ea fiber ea lik'hemik'hale, joalo ka letlooa la pickling indastering ea electroplating.