Sebopeho

Lisebelisoa

Vin 1.4404 / Aisi 316l, Din 1.8539 / Aisi 9044l

Monel, Photosonel, Junes Steel, Hasstoy

Lisebelisoa tse ling tse fumanehang ka kopo.

Phokotso ea filthara: Microns ea 1 -100

Litlhaloso

| Tse-boholo ba Meshi e mehlano ea Meh | ||||||||

| Tlhaloso | Ho fola | Sebopeho | Botenya | Poroniki | Ho nepahala ha moea | Rp | Boima | Khatello ea bubble |

| μm | mm | % | (L / Min / cm²) | N / cm | kg / ㎡ | (MMH₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-6-400 |

| SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + 325 + 100 + 100/64 + 64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 12/64 + 64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 100/64 + 64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

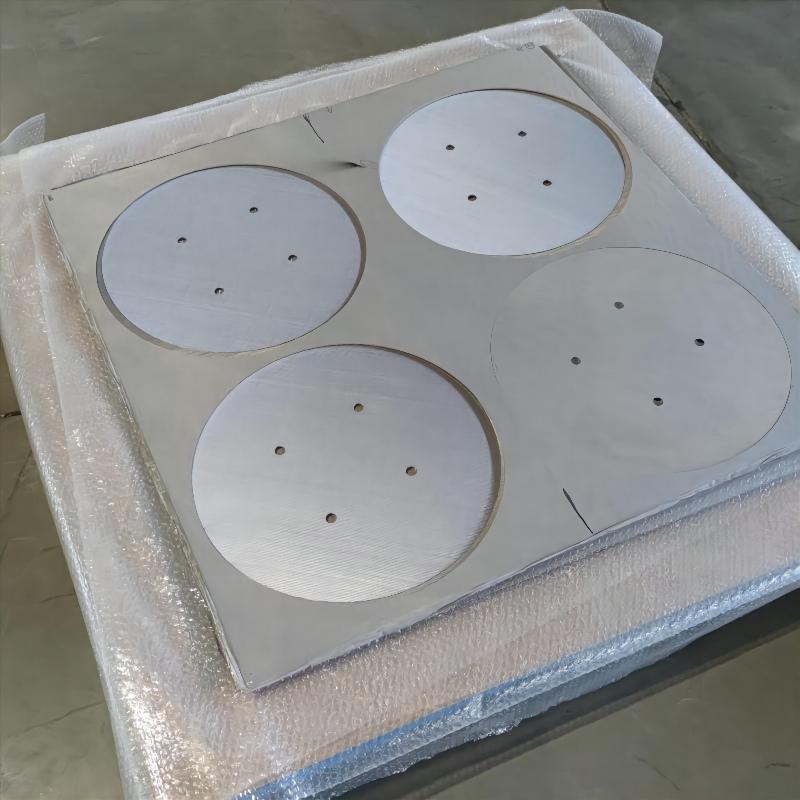

Boholo

Bophara: 5mm-1500mm

Kholo ho feta 1500mm, re hloka Splice.

Likopo

Libethe tsa mokelikeli, lifilimi tsa Nutsche tsa Nutsche, ho felisoa ha li-silos, lits'ebetso tsa li-blowchnology.

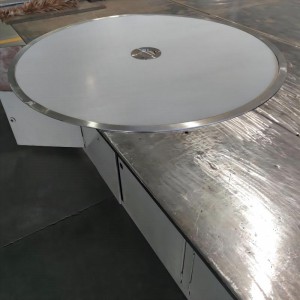

Sebopeho se tloaelehileng se tloaelehileng se senyehileng se arotsoeng ka likarolo tse 'ne: Karolo e sirelletsang, letsopa la sefahleho le skeleton le skeleton. Mofuta ona oa sefahleho ha se feela ho nepahala o ts'oanang le o tsitsitseng, empa o na le matla a maholo ebile a thata haholo. Ke boitsebiso bo botle ba filthara tse nang le linako tse ling moo ho hlokahalang. Hobane mochine oa eona oa ho falla o phahama, 'me Seteishene sa Meshi ba mokokotlo mme se ka sebelisoa mesebetsing e tsoelang pele le e sa laoleheng. Lingoliloeng tsena li bonolo ho li theha, ho sebetsa le ho ts'oaroa, 'me li ka sebetsoa ka mefuta e fapaneng ea lintho tsa mafu a mangata, cylimical, e bua le ho kotula ebile e khomaretsoe.

tšobotsi

1. Matla a phahameng le ho ba thata haholo: E na le matla a maholo le matla a hatellang, ho sebetsa hantle, ho sebetsa hantle le ho ba bonolo ho o sebelisa.

2. Karolo e tsitsitseng le e tsitsitseng

3. Liphetoho tse fapaneng tsa libaka tse sebelisang: E ka sebelisoa tikolohong ea mocheso oa -200 ℃ ~ 600 ℃ le ho fifala ha tikoloho ea acid-setsi.

4. Ts'ebetso e Ntle ea ho Hloekisa: Tšusumetso e ntle ea tlhoekiso ea ho hloekisa

Khamphani e na le lisebelisoa tsa ntlafatso tsa machabeng, sehlopha sa sekolo sa R & d, sehlopha sa mahlale a setsebi, marang-rang a phetheselang. Re tla tsoela pele ho ntlafatsa boleng le boemo ba rona, 'me ra tsoele pele ho fihlela litlhoko tse fapaneng tsa bareki tse nang le ts'ebeletso e ntle ea boleng bo botle le ho nahanoang.