Sebopeho

Lisebelisoa

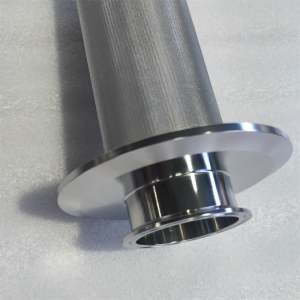

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, tšepe ea Duples, li-alloys tsa Hastelloy

Lisebelisoa tse ling tse fumanehang ka kopo.

Filter fineness: 1 -100 microns

Litlhaloso

| Tlhaloso -Standard five-layer sintered mesh | ||||||||

| Tlhaloso | sefa fineness | Sebopeho | Botenya | Porosity | Moea o Permeability | Rp | Boima ba 'mele | Khatello ea Bubble |

| μm | mm | % | (L/min/cm²) | N/cm | kg / ㎡ | (mmH₂O) | ||

| SSM-F-1 | 1 | 100+400x2800+100+12/64+64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-600 |

| SSM-F-2 | 2 | 100+325x2300+100+12/64+64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100+200x1400+100+12/64+64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100+165x1400+100+12/64+64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100+165x1200+100+12/64+64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100+165x800+100+12/64+64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100+165x600+100+12/64+64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100+400+100+12/64+64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100+325+100+12/64+64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100+250+100+12/64+64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100+200+100+12/64+64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100+150+100+12/64+64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

Lisebelisoa

Libethe tse nang le metsi, lihloela tsa Nutsche, Centrifuges, Aeration ea li-silos, lisebelisoa tsa biotechnology.

Molao-motheo oa letlooeng la sintered: sekoahelo se entsoeng ka sekoahelo se entsoeng ka sekoahelo se entsoeng ka letlapa le tloaelehileng (lesoba le pota-potileng kapa sekoti se sekoere) le likarolo tse 'maloa tsa sekoahelo sa sekoti (kapa letlooeng le teteaneng) sekontiri se entsoeng ka kakaretso, se nang le moea o motle oa ho phunyeletsa. mesh e sephara e lohiloeng, le matla a mochini a poleiti e nang le perforated.Ha e na moea o kenang hantle feela, empa hape e na le litšoaneleho tsa phapang ea khatello e tlase, ho nepahala ho phahameng, le ho hloekisa mokokotlo o motle haholo.E 'nile ea sebelisoa haholo ho phekola metsi, lino, lijo, metallurgy, lik'hemik'hale le liindasteri tsa meriana.Ka nako e ts'oanang, k'hamphani ea rona e ka etsa marang-rang a khethehileng a kabo ho latela maemo a ho sebetsa a moreki, 'me ea hlahisa marang-rang a entsoeng ka Monel, alloy ea titanium le lisebelisoa tse ling.

Likarolo tsa Sintered mesh:

1. Sintered mesh e na le matla a phahameng le ho tiea ho hotle: e na le matla a phahameng a mochine le matla a khatello, ts'ebetso e ntle, ts'ebetso ea welding le kopano, 'me e bonolo ho e sebelisa.

2. Ho nepahala ka mokhoa o ts'oanang le o tsitsitseng oa sintered mesh: Ts'ebetso e ts'oanang le e tsitsitseng ea ho hloekisa e ka finyelloa bakeng sa lintlha tsohle tse nepahetseng tsa ho hloekisa, 'me mesh ha e fetohe nakong ea tšebeliso.

3. Tloaelo e tloaelehileng ea mekhahlelo e mehlano: e na le likarolo tse 'nè: lera le sireletsang, lera la filthara, lera la karohano le lera la tšehetso la lihlopha tse peli.

4. Sintered mesh e na le matla a phahameng le ho tiea ho hotle: e na le matla a holimo haholo a mochini le matla a hatellang.