Sebopeho

Lisebelisoa

Vin 1.4404 / Aisi 316l, Din 1.8539 / Aisi 9044l

Monel, Photosonel, Junes Steel, Hasstoy

Lisebelisoa tse ling tse fumanehang ka kopo.

Phokotso ea filthara: 1 -200 likonopo

Litlhaloso

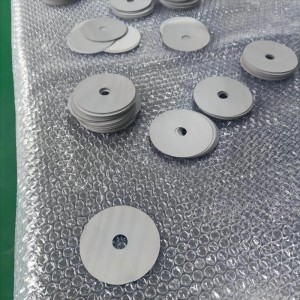

| TLHOKOMELISO - Pula ea Plate Plate Thoush | ||||

| Tlhaloso | Ho fola | Sebopeho | Botenya | Poroniki |

| μm | mm | % | ||

| SSM-P-1.5t | 2-100 | 60 + 30 + φ4X5PX1.0t | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | 30 + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + 30 + φ4X5PX1.5t | 2.5 | 35 |

| SSM-P-P-3.0t | 2-200 | 60 + φ6x8px2.0t | 3 | 35 |

| SSM-P-4.0t | 2-200 | 30 + 20 + φ8X10PX2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 + 30 + 16 + 18 + φ8x10Px3.0t | 5 | 55 |

| SSM-P-6.0t | 2-250 | 30 + 30 + 17 + φ8x10Px4.0t | 6 | 50 |

| SSM-P-7.0t | 2-250 | 30 + 16 + 32 + φ8XTPX5.0t | 7 | 50 |

| SSM-P-8.0t | 2-250 | 30 + 16 + 10 + φ8x10Px6.0t | 8 | 50 |

| Bothusi ba poleiti ea ho putlama le sebopeho sa mehoe e ka etsoa ho latela litlhoko tsa mosebelisi. | ||||

Ho bua ka mantsoe, haeba e sebelisoa ho li-filthara tsa 'mele, sebopeho sa poleiti se sephara se ka ba maemong a mekhahlelo a mekhahlelo e mehlano ea mekatola le ho putlama polane e senyehileng hammoho.

Eo ke 100 + filyal "100 + 12 + 12/64 + 64 + 64 + 43t (kapa e le 'ngoe e otla poleiti)

Bothuni ba purete ea ho putlama le tsona li ne li itšetlehile ka tlhoko ea hau ea khatello ea khatello ea khatello ea khatello ea khatello ea khatello

Sehlahisoa sena se loketse libaka tsa khatello tse phahameng kapa khatello e phahameng ea ho rarolla indastering e tsoelang pele ea indasteri ea pharma le la lik'hemik'hale le litlhokahalo tsa tlhahlobo.

Likopo

Lijo tsa lijo le tse fapaneng, tšoaro ea metsi, e tlosang lerole, meriana, k'hemik'hale, Plymer, joalo-joalo.

Karolo e tloaelehileng ea mesh e sikiloeng e sitsoeng ho eona e tsamaisoa haholo ke mofuta oa sefatsana sa methapo e tloaelehileng ea Mesh e Sirelelitsoeng ea Mesh. Meshi ea methapo e tloaelehileng ea terata ea methapo ea terata ea methapo e entsoe ka likarolo tse hlano tsa methapo ea tšepe e nang le mapheo a tšepe e ngata haholo le vacuum. Karolo ea sefahleho e entsoeng ka litlolo tse hlano tse mpe tsa mesi e se nang litšila e na le litšobotsi tse matla tsa moea, tsa bohloeki le se hloekileng sa terene le tse sa tsoa tšolola.

Meshera e 'ngoe le e' ngoe ea karolo e 'ngoe ea tšenyo e mpe ea tšepe e kenella ho theha sebopeho se tšoanang le se loketseng, se nang le matla a maholo, le mesifa e ntle le mesifa. Bokhoni bo sa tsitsang joalo ka karolo e tšoanang le boqapi bo lekaneng, bo phethahetseng le ho hanyetsa, ho hanyetsa mocheso le ts'ebetso e felletseng ho molemo. E phahameng ho feta mefuta e meng ea lisebelisoa tsa filthara.

1. Likarolo tsa sehlahisoa:

1) Mesh e nang le ts'enyo e mehlano e entsoe ka seka sa ho sireletsoa, mokato oa sefahleho, sets'oants'o sa sefahleho, se bonojoang le likarolo tse peli tsa Skeleton;

2) Matla a phahameng: Kamora hore a sebeletse mohala oa lehora a mehlano, e na le matla a maholo le matla a hatellang;

3) Ho nepahala ho phahameng: Ho ka kenya tšebetsong ts'ebetso ea Filform ea Folotration bakeng sa phallo ea FALTRATER VICTOLE EA 1 ho 200um;

4) Khanyetso ea mocheso: E ka sebelisoa bakeng sa ho fetela pele ho tloha khale ho fihlela ho fihlela ho fihlela ho isa ho likhato tse 650;

5) Ho hōleloa: Ka lebaka la sebopeho sa setlama se holimo se nang le phello e ntle ea ho hloekisa, ho hloekisa e bonolo.

6) E na le ho loka hantle le matla a boima, ha ho na lebaka la ho thibela taolo ea tšehetso ka nako e telele, ho bonolo ho e hloekisa ebile ha ho bonolo ho e lematsa.

2.To sepheo sa mantlha:

1) E sebelisoa e le thepa e phoroselang e pholileng ka mocheso o phahameng oa mocheso;

2) E sebelisoa bakeng sa kabo ea khase, ntho ea li-orifices bakeng sa bethe e lekantsoeng;

3) Bakeng sa ho nepahala ho matla, lisebelisoa tse phahameng tsa filthara tse phahameng haholo;

4) bakeng sa khatello e phahameng ea mokokotlo ka morao

5) E sebelisoa bakeng sa ho thella ha polyester, lihlahisoa tsa oli, meriana le libui le lihlahisoa tsa lik'hemik'hale le tsa lik'hemik'hale.

Tlhokomeliso: Litekanyetso li ka hlahisoa ho latela litlhoko tsa bareki. E ka sebetsoa ho tubulalar, disc, kerese le lintho tse ling tsa filthara.