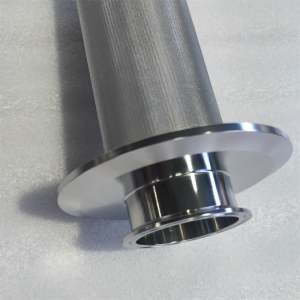

Sebopeho

Lisebelisoa

Vin 1.4404 / Aisi 316l, Din 1.8539 / Aisi 9044l

Monel, Photosonel, Junes Steel, Hasstoy

Lisebelisoa tse ling tse fumanehang ka kopo.

Phokotso ea filthara: Microns ea 1 -100

Litlhaloso

| Tse-boholo ba Meshi e mehlano ea Meh | ||||||||

| Tlhaloso | Ho fola | Sebopeho | Botenya | Poroniki | Ho nepahala ha moea | Rp | Boima | Khatello ea bubble |

| μm | mm | % | (L / Min / cm²) | N / cm | kg / ㎡ | (MMH₂o) | ||

| SSM-F-1 | 1 | 100 + 400x2800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 1.82 | 1080 | 8.4 | 360-6-400 |

| SSM-F-2 | 2 | 100 + 325x2300 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.36 | 1080 | 8.4 | 300-590 |

| SSM-F-5 | 5 | 100 + 200x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 2.42 | 1080 | 8.4 | 260-550 |

| SSM-F-10 | 10 | 100 + 165x1400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.08 | 1080 | 8.4 | 220-500 |

| SSM-F-15 | 15 | 100 + 165x1200 + 100 + 12/64 + 64/12 | 1.7 | 37 | 3.41 | 1080 | 8.4 | 200-480 |

| SSM-F-20 | 20 | 100 + 165x800 + 100 + 12/64 + 64/12 | 1.7 | 37 | 4.05 | 1080 | 8.4 | 170-450 |

| SSM-F-25 | 25 | 100 + 165x600 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.12 | 1080 | 8.4 | 150-410 |

| SSM-F-30 | 30 | 100 + 400 + 100 + 12/64 + 64/12 | 1.7 | 37 | 6.7 | 1080 | 8.4 | 120-390 |

| SSM-F-40 | 40 | 100 + 325 + 100 + 100/64 + 64/12 | 1.7 | 37 | 6.86 | 1080 | 8.4 | 100-350 |

| SSM-F-50 | 50 | 100 + 250 + 100 + 12/64 + 64/12 | 1.7 | 37 | 8.41 | 1080 | 8.4 | 90-300 |

| SSM-F-75 | 75 | 100 + 200 + 12/64 + 64/12 | 1.7 | 37 | 8.7 | 1080 | 8.4 | 80-250 |

| SSM-F-100 | 100 | 100 + 150 + 100 + 100/64 + 64/12 | 1.7 | 37 | 9.1 | 1080 | 8.4 | 70-190 |

Likopo

Libethe tsa mokelikeli, lifilimi tsa Nutsche tsa Nutsche, ho felisoa ha li-silos, lits'ebetso tsa li-blowchnology.

Molao-motheo oa Meshe o Ileng oa Sebetso: Meshi e senyehileng e entsoe ka thepa e tloaelehileng ea poleiti (kapa lesoba le nang le moea Ha baa nepatho ba ho nepahala ho lokile, empa hape e na le litšobotsi tsa phapang e tlase ea khatello, e nepahetseng le ho hloekisang haholo. E se e sebelisoa haholo kalafong ea metsi, e leng seno, lijo, thepa ea metallishene, indasteri ea lik'hemik'hale le ea meriana. Ka nako e ts'oanang, k'hamphani ea rona e ka rala le marang-rang a ngotsoeng ho latela maemo a sebetsang a moreki, 'me a hlahise le netweke e entsoeng ka poleiti ea poleiti e entsoeng ka poleiti

Litšobotsi tsa Meshi ea Tesh:

1. Mesh e senyehileng e na le matla a maholo ebile e ntle e na le matla a maholo le matla a mangata, ho sebetsa hantle le kopano, 'me ho bonolo ho se sebelisa.

2. Se hlakileng le se bulehileng sa MESH: Ts'ebetso ea mofuta o sa tsoakoang le e sa fetoheng le e sa lumellaneng e ka fihlella bakeng sa mekhoa eohle, 'me mesh ha e fetohe nakong ea tšebeliso.

3. Tekanyetso e tloaelehileng ea karolo ea mahlano:

4. Mesh e senyehileng e na le matla a maholo ebile e le thata haholo: Ho na le matla a mangata haholo le matla a hatellang.