Litlhaloso

Lintlha tsa 3003 Aluminium.

Al: 98.7%, Mn: 1% - 1.5%, Cu: 0.05% - 0.2%, Fe: 0.7% max, Zn: 0.1% max, Si: 0.6 max.

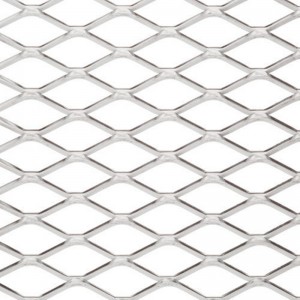

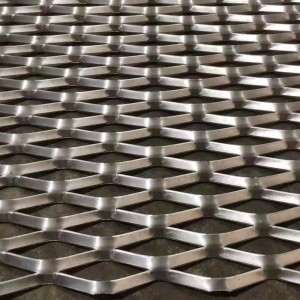

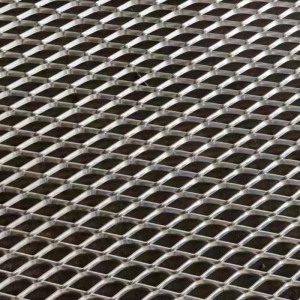

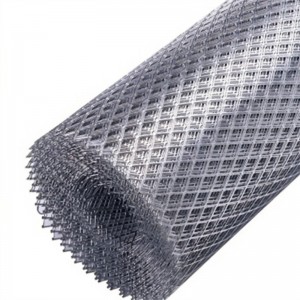

Lipampiri tse nyane tsa tšepe tse atolositsoeng tsa aluminium.

12" × 12", 12" × 24", 12" × 36", 12" × 48", 24" × 24", 24" 36", 24" 48", 36" × 36", 36" × 48" (boholo bo bong ba lakane boa fumaneha ha u kopa).

| Tlhaloso - aluminium e atolositsoeng tšepe | |||||||

| Setaele | Boholo ba moralo (inch) | Boholo ba ho bula (inch) | Boholo ba strand (inch) | Sebaka se bulehileng (%) | |||

| SWD | LWD | SWO | LWO | Botenya | Bophara | ||

| SAEM1/2"-0.05 | 0.5 | 1.2 | 0.375 | 0.937 | 0.05 | 0.09 | 65 |

| SAEM1/2"-0.05F | 0.5 | 1 | 0.312 | 1.000 | 0.04 | 0.10 | 61 |

| SAEM1/2"-0.08 | 0.5 | 1.2 | 0.375 | 0.937 | 0.08 | 0.10 | 60 |

| SAEM1/2"-0.08F | 0.5 | 1 | 0.312 | 1.000 | 0.06 | 0.11 | 58 |

| SAEM3/4"-0.05 | 0.923 | 2 | 0.812 | 1.750 | 0.05 | 0.11 | 78 |

| SAEM3/4"-0.05F | 0.923 | 2 | 0.750 | 1.812 | 0.04 | 0.12 | 72 |

| SAEM3/4"-0.8 | 0.923 | 2 | 0.750 | 1.680 | 0.08 | 0.13 | 76 |

| SAEM3/4"-0.8F | 0.923 | 2 | 0.690 | 1.750 | 0.07 | 0.14 | 70 |

| SAEM1-1/2"-0.8 | 1.33 | 3 | 1.149 | 2,500 | 0.08 | 0.13 | 81 |

| SAEM1-1/2"-0.8F | 1.33 | 3 | 1.044 | 2,750 | 0.06 | 0.14 | 78 |

| Hlokomela: | |||||||

| Litekanyo tse ka holimo li sebelisoa ka tloaelo, empa li hakanyetsoa feela. | |||||||

| Mamello ea 10% e lumelloa ka litekanyo. | |||||||

Ho na le mabitso a mangata bakeng sa mesh ea tšepe e atolositsoeng ea aluminium: letlooeng la aluminium e atolositsoeng, letlooeng le atolositsoeng la aluminium, mesh ea aluminium e khabisitsoeng, letlooeng la lerako la aluminium, letlooeng la lerako la aluminium, letlooeng le otlolohileng la aluminium, letlooa le atolositsoeng la fluorocarbon le fafalitsoeng ka aluminium, letlooeng la aluminium, letlooeng le atolositsoeng la aluminium, aluminium oxide e atolositsoeng letlooeng, aluminium ea kantle ea lebota e atolositsoeng letlooeng, aluminium e khabisitsoeng e atolositsoeng letlooeng, siling aluminium e atolositsoeng letlooeng, joalo-joalo.

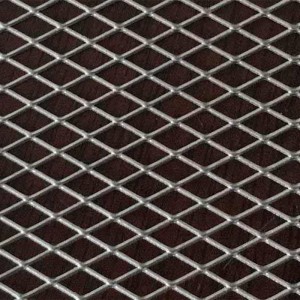

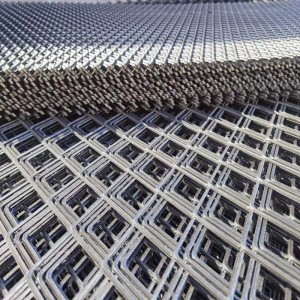

E entsoe ka poleiti ea pele ea aluminium ka ho seha le ho holisa ka theknoloji e ncha.'Mele oa eona oa letlooeng o bobebe ebile o na le matla a ho jara.Mesh e tloaelehileng e atolositsoeng ea aluminium e na le masoba a bōpehileng joaloka daemane, 'me mefuta e meng ea masoba e kenyelletsa masoba a hexagonal, a chitja, a khutlotharo le a sekala.E sebelisoa haholo mokhabisong oa meralo, lerako la lesira la tšepe, siling, tšireletso, ho sefa, ho etsa mesebetsi ea matsoho, jj.

Lintho tse bonahalang: poleiti ea aluminium, poleiti ea aluminium alloy, joalo-joalo.

Mokhoa: Letlapa la aluminium le otlolloa ke mochini oa tšepe o atolositsoeng oa aluminium le mochini oa ho kuta.

Likarolo tsa aluminium mesh ea tšepe e atolositsoeng: ha e na mafome le 'mala o motle.Ha aluminium e atolositsoeng tšepe letlooeng sebelisoa ho lerako le ka ntle lesira la mokhabiso meralo, ka lebaka la ho tiea e ikhethang ea thepa ea eona ea tšepe, ho ka ba bonolo hanela tlhaselo ea maemo a mabe a leholimo a kang lifefo, 'me ka nako e tšoanang, ho bonolo ho Tlhokomelo, ho latela pono ea ho shebella, mesh ea tšepe e atolositsoeng ea aluminium e na le phello e matla ea likarolo tse tharo mme e fa batho thabo ea pono.Ha e sebelisoa e le marulelo a ka hare kapa lerako la karohano, ho phunyeletsa ho ikhethang le ho phatsima ha thepa ea eona ho etsa hore sebaka se be le monyaka o motle haholoanyane.

Lihlahisoa tsa rona li na le mehlala e mengata le litlhaloso tse feletseng;li na le litšoaneleho tsa mebala e metle, ponahalo e ntle, e matla ebile e tšoarella, boleng bo holimo, le maemo a holimo.Li rekisoa mose ho maoatle 'me li hapile thoriso e le 'ngoe.

Mosebetsi: Haholo-holo e sebelisetsoa mokhabiso oa meralo, lerako la lesira la tšepe, siling, tšireletso, ho sefa, ho etsa mesebetsi ea matsoho, joalo-joalo.

Mesh e atolositsoeng ea aluminium e boetse e na le li-apertures tse ling tse sa tšoaneng: litlhaloso tse joalo tse atolositsoeng tsa aluminium letlooeng li ntlafatsoa ka ho ntlafatsa likarolo tsa phepelo ea lisebelisoa tsa ho lata, e le hore li ka hlahisa mesh e atolositsoeng ea aluminium e nang le lisebelisoa tse ngata ka mechine e menyenyane le lisebelisoa, e etsa hore e bonahale e le ntle. seatla se bulehileng.